#1 Harvest and Grain Marketing Plan

In this series of 5 videos Jon Dadd, Territory Manager for Corteva Agriscience, describes the key factors for successful grain storage.

The next generation of grain protectants.

Conserve Plus is a next generation grain protectant; it offers grain growers unprecedented flexibility to store cereal grains on farm, whilst delivering robust grain protection. It contains the active ingredients Qalcova active and s-methoprene, which provide flexibility to treat all cereal grains, including malt barley and maize.

Conserve Plus is the latest addition to the Conserve family. It is a novel formulation, combining Qalcova® active (Spinosad) and S-methoprene at 100 gm ai per L. Conserve Plus will be able to be used on all cereal grains, including malt barley.

Product details

Conserve Plus offers grain growers unprecedented flexibility to store cereal grains on farm, whilst delivering robust grain protection

View now

Conserve Plus is a next generation grain protectant; enabling growers to control insect pests, including the resistant Lesser Grain Borer, in on-farm storages for up to 9 months

View now

Keep this decision tree to remember OP selection rationale and prompt WHP expiry date recording once treatment occurs

View now

Please sign the End User Declaration (EUD) Form when purchasing Conserve Plus.

Sign nowIn this series of 5 videos Jon Dadd, Territory Manager for Corteva Agriscience, describes the key factors for successful grain storage.

1:48

In this series of 5 videos Jon Dadd, Territory Manager for Corteva Agriscience, describes the key factors for successful grain storage.

Australia’s grain industry relies heavily on insecticides to both fumigate and protect grain so that it meets market requirements for insect-free grain. Resistance of grain insects to phosphine fumigation and protectant insecticides is becoming a major problem in Australia. It is expected that the number of resistant insects found will increase over the next five years and is likely to extend across all key grain growing regions.

Prolonging the effective life and availability of fumigants and insecticides, through careful management of resistance, is in the interests of everyone involved in the grains industry.

The GRDC Stored Grain Information Hub is a good place to get up to date information on monitoring grain to identifying key pests.

Qalcova® active (Spinosad) is now established as the most important active ingredient for controlling LGB resistant to methoprene and/or deltamethrin. The combination of Qalcova® active (nerve acting toxin) and s-methoprene (juvenile hormone analogue) targets the key pest LGB, whilst also providing broad spectrum activity on other key insects.

Conserve Plus delivers robust grain protection, via a significant dose increase over Conserve On-Farm, which is an important step to mitigate the development of resistance.

The table below presents data from a recent study at University of Queensland. Good control of adults and progenyof these key grain pests can be seen for at least nine months.

Australia’s grain industry relies heavily on insecticides and fumigants to protect stored grain from insect pests. As a result, resistance of grain insects to phosphine

and protectant insecticides, has become a major problem. It is expected that the number of resistant insect populations found will increase over the next five years and is likely to extend across all key grain growing regions.

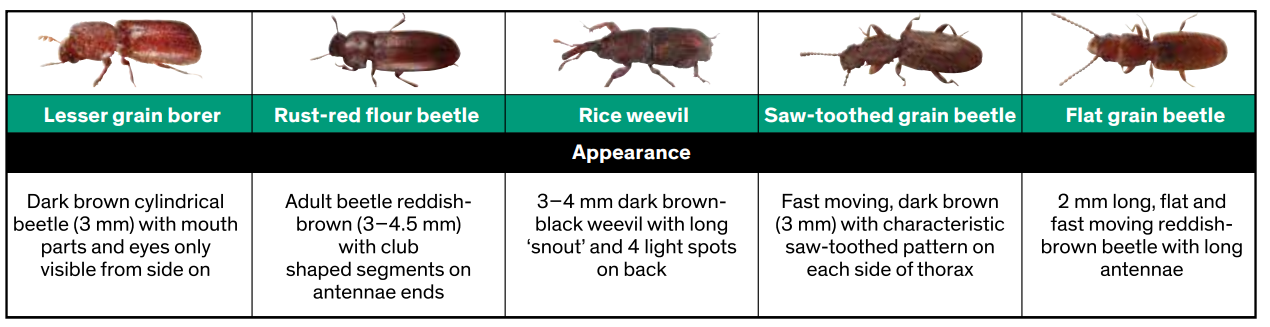

A key issue is that none of the protectant insecticide active ingredients currently available control all of the five key insect pests. As such, combinations of actives are necessary to control diverse populations, of susceptible and tolerant insects, which occur naturally.

The diagram below is a summary of resistance testing up to 2010, indicating the historical use of s-methoprene in combinations with OP’s, targeting LGB. This extension of resistance to OP’s shows that it is critical for growers to rotate to protectants using Qalcova® active or deltamethrin, to mitigate the development of resistance in LGB.

For more information, download the Technical Manual.

Grain protectants must be applied to grain free of pests, and are most effective when grain is treated into clean facilities. The following steps will help ensure grain storages begin and remain insect-free for the storage duration.

Know the key pests:

Remove insect food sources and control the base insect population. Good hygiene is critical to reducing the overall potential insect burden.

Prepare the grain protectant spray application and augering systems.

The position of the spray line nozzle can vary on the equipment, determined primarily on the auger barrel length. If the nozzle is too close to the hopper on longer augers, it can create too much drag and affect elevator output.

The nozzle must be positioned to allow suitable coverage and mixing as the flyting lifts the grain up and into the storage. The nozzle location must allow ease of access to check for spray pattern and nozzle blockages which can occur in the presence of grain dust, as well as calibration checks.

Apply the grain protectant ensuring all grain is protected.

Effective application of grain protectants relies on the even distribution of a very small amount of pesticide throughout the entire grain mass. Uneven distribution may leave pockets or layers of unprotected grain where insect infestation may occur. Always use an auger when applying Conserve Plus. Corteva Agriscience does not support the use of tubeveyors, due to poor mixing/coverage issues.

Once the grain protectant has been applied:

Manipulate the storage environmental to limit or prevent insect reproduction. Cool and dry environments are least favourable for storage insects, as evidenced in the table to the right.

Conserve Plus (when applied correctly and at the label rate) treats grain at 1 ppm (1 g Qalcova® active / tonne of grain). There is a nil withholding period (WHP) for human and animal consumption, and importantly there are no meat residue bioaccumulation concerns for livestock fed with treated grain.

An Australian cereal grains maximum residue limit (MRL) has been set for Qalcova® active at 1 ppm, which is the same as the amount applied to the grain. Other markets varying from 1 to 2 ppm depending on the country and commodity treated.

Due to the slow degradation of Qalcova® active, in short to mid-term storage scenarios, the residue on the grain at out-turn will be at, or just below, the original level at treatment (i.e. at the Australian MRL) as indicated in the graph below (Corteva Agriscience™ internal trial).

To ensure that there is no risk to trade it is important to ensure that any grain protectant containing Qalcova® active is only applied once over the life of the commodity.

MRLs for Qalcova® active in cereal grains have been established in all key Australian cereal grain markets including, Australian domestic, EU, Japan, USA, Taiwan and all countries that accept Codex residue limits.

Information on MRLs:

The purchase and use of Conserve Plus is governed by a stewardship program in addition to label Directions for Use. Together, the label and stewardship program are designed to minimise the risk of a double application of Qalcova® active to prevent trade issues which may arise through MRL breaches.

The Conserve Plus Directions for Use:

For more information, download the Technical Manual